Brew # 9 - Morgan’s Balter XPA Clone

Another extract brew - this time, I'm following a Balter XPA clone recipe

Ingredients

- Morgan's Pacific Pale Ale kit (1.7kg)

- 1.5kg Morgan's Master Malt Extra Pale Liquid Malt Extract

- Morgan's American Ale Yeast (15g)

- ~30g Amarillo hop pellets

- ~40g Citra hop pellets

- ~15g Centennial hop pellets

Method

Brew day

- Filled basin with hot water and stood the two liquid malt extracts in to soften

- Boiled ~500mL of cold filtered water and added to glass flask for yeast rehydration (see below)

- Filled Ferm'us with cold filtered water to 5L mark

- Boiled another 1.7L water (that's the max my kettle can take)

- Poured ~1L of the boiling water into the Ferm'us

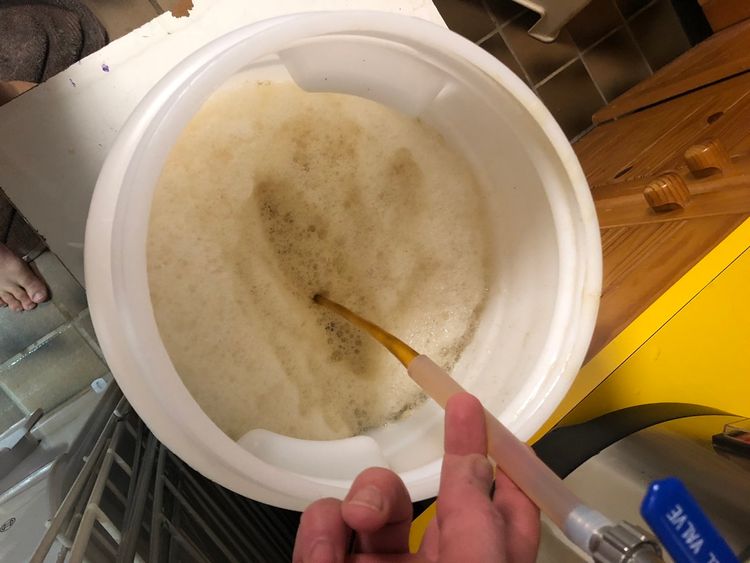

- Emptied the wort and liquid malt extract tins into the Ferm'us

- Used the rest of the boiling water to rinse the tins

- Lifted the Ferm'us and gave everything a good shake to mix the wort and LME and give a bit of oxygenation (much easier with only ~8L in the Ferm'us instead of 20L like I did before)

- When I removed the pressure lid the seal dropped into the wort!!! It was sanitised, so it shouldn't cause too much harm, but I had to squeeze my arm into the Ferm'us to be able to reach far enough in to grab it when I finally managed to pull it out of the wort

- Topped up with more cold filtered water to 23L - I didn't need any additional boiling water and hit a final temp around ~27C, which is just about perfect

- Placed the Ferm'us into a temp controlled fridge at 22C

OG: 1.066 (I think this was wrong and due to the higher density wort at the bottom of the Ferm'us)

Yeast prep & pitching

- Allowed the temperature of the 500mL pre-boiled water (in the flask - see above) to chill to ~28C

- Placed the flask in the temp controlled fridge (22C) and allow to rehydrate for 15-30 minutes

- I didn't add any wort to the yeast this time

- Gently (no splashing) swirled the flask to suspend the yeast in the liquid

- Poured the yeast mixture into the Ferm'us

- Attached pressure release valve (PRV) to the pressure kit

- Monitored every few hours and adjust the PRV to ensure the Ferm'us doesn't become over-pressurised

Primary Fermentation

- After pitching the yeast the temp rose to around 27C

- I attached the fridge to the temp controller (wasn't attached as I wasn't expecting it to be that high!) and set the temp to 26.5C

- I reduced steadily over 4 days to 24C - by this stage the heater was kicking in to maintain the temp, but I figured it was better to drop slowly than bring it down too quickly and annoy the yeast

- Left for 4 days

Trub Collection

- On day 4 primary fermentation appeared done (didn't measure SG), so I attached a sanitised, empty collection bottle to start collecting the trub

- After 24 hours, detached and emptied the trub from the collection bottle

- Rinsed and sanitised the collection bottle for dry hopping

Dry Hopping

- Added ~30g of Amarillo hop pellets (9.2% AA), ~40g of Citra hop pellets (13.9% AA), and ~15g of Centennial hop pellets (8.8% AA) via a sanitised collection bottle - this was slightly more than the suggested 24g, 40g, and 12g, but I like it hoppy

Crash Cool

- Because the temp was still up around 24C, I started the crash cool straight after dry hopping to hit the target 3C after 7 days

- Temperature controller was used to reduce the temperature by 0.3C every two hours, which means we'll hit 3C after ~6 days

Keg & Carbonate

- Sanitised a keg and placed in the keezer to chill

- Pressurised to ~6PSI

- Transferred the beer from Ferm'us to keg under pressure

- Placed the keg in the keezer

- Attached CO2 at 39PSI to force carbonate for ~24 hrs

- Allowed to stand for ~1 week to condition

Improvements

- Take photos (again)!!

- Don't drop the pressure lid seal into the wort