Brew # 20 - Bohemian Pilsner

It's been a while since I last brewed...kinda fell out of the habit, and there's so many good beers available from any bottle shop these days. But I just turned the big 5-0 and some very kind friends decided they wanted to buy me a big present. So I took the opportunity to purchase a Grainfather S40.

For my first all grain brew, I decided I'd like to brew a Pilsner. Summer's coming...nuff said.

Start date: 11th September 2022

Equipment

- Grainfather S40 with wort chiller (new)

- Hop spider (new)

- Stainless steel mash paddle (new)

- Refractometer (new)

- 19 litre stainless steel stockpot w/ lid

- Induction cooktop

- Digital thermometer

- Snub-nose Fermentasaurus ("Fermus") w/ pressure lid

- Sanitiser in spray bottle

- Long handle spoon

Ingredients

- 4.3kg Weyermann Pilsner Malt (milled)

- 150g Weyermann Carahell (milled)

- 500g Light Dry Malt Extract

- 30g Hallertau Perle @ 6.7% (60 min)

- 30g Czech Saaz @ 3.6% (30 min)

- 30g Czech Saaz @ 3.6% (15 min)

- Bluestone Pilsen Liquid Yeast

- Irish moss

Cleaning/Sanitising

All the new kit got a proper clean and rinse.

The Fermus was washed sanitised before it was stored (properly), but that got another rinse and sanitisation. Rinsed with cooled boiled water and left to dry in the sun. UV is a great sanitiser (I think?).

Brew Day

- Heat 19L of tap water (unfiltered) to 71C (impressed how fast the Grainfather heated the water)

- Add all grains to mash tun

- Mash for 30mins @ 62C

- Turn on the recirculation pump

- Strike temp was a bit too high, so started at ~65C

- After 30mins, I raised the temp to 71C for another 30 mins

- Started heating sparge water to ~80C using the stock pot and induction cooktop - the app said to use 10L for sparge, but I heated 12L, just in case (better to have more than you need than not enough)

- After 30 mins, I raised the mash tun and pour sparge water to rinse

- I wasn't sure if there was a technique for this - I just tried not to pour the water too quickly and ensured I covered all areas

- Raise temp on Grainfather to 103C to boil

At this stage, I dunked a finger to test the wort. I was a bit surprised to find that it wasn't very sweet. It tasted like it was a bit watery, so I decided I was going to need to add the DME. Prior to this, it hadn't been part of the recipe.

So, once the wort was boiling, I slowly poured the dry malt extract into the boil and placed the hop spider into the wort.

At this point, instead of adding 30g of Perle @ 6.7%, I accidentally added 35g of Saaz @ 3.6%. I didn't realise until I added the second batch of Saaz (35g) at 30 mins. So I added the Perle (35g) here, too. Time will tell if this makes a big difference to the flavour.

With 15 minutes to go I added the final 30g of Saaz hops, bringing the total to 135g...could be a very hoppy lager!

I probably should have added the wort chiller at this stage, to sanitise in the boiling wort, but I didn't add this until the hour was up and I'd removed the (heavy) hop spider. I added the Irish moss at this time, too. That meant I ended up boiling for a bit longer than the hour.

With the chiller in place and sanitise, I turned the heating element off and cranked the cold water. At the same time, I started to stir the wort counter-clockwise, which is opposite to the flow of the water in the chiller.

After ~15 minutes, the temperature was down to 23C, just above room temperature. I used the refractometer, which I'd calibrated earlier, to measure the specific gravity.

OG: 1.055

Transferring the wort to the Fermus using the tap on the side of the Grainfather was really straightforward, and even easier when I attached the pipe from the recirculation arm.

Once the wort was transferred, I shook the wort to aerate, then the Fermus was place in the fermenting fridge with temperature controller set to 7C. The yeast packet was added to the fridge, too, to stabilise the temp of both.

After ~24hrs, the temp was settled at 7C. Gave the wort another big shake and then pitched the yeast straight from the pack (as per the instructions).

Primary Fermentation

Note: I recently read that fermenting under pressure might not be so good for lager yeast, so I'm going to keep the release valve open this time and allow the pressure to constantly equalize. I figure this isn't any different from attaching a PRV.

- Start at 7.5C

- Raise temp in 12x 0.2C increments every 3 hours

- Temp should hit 9.9C after 36 hours

- Then raise in 0.2C increments every 2 hours to reach ~12C after another 24 hours

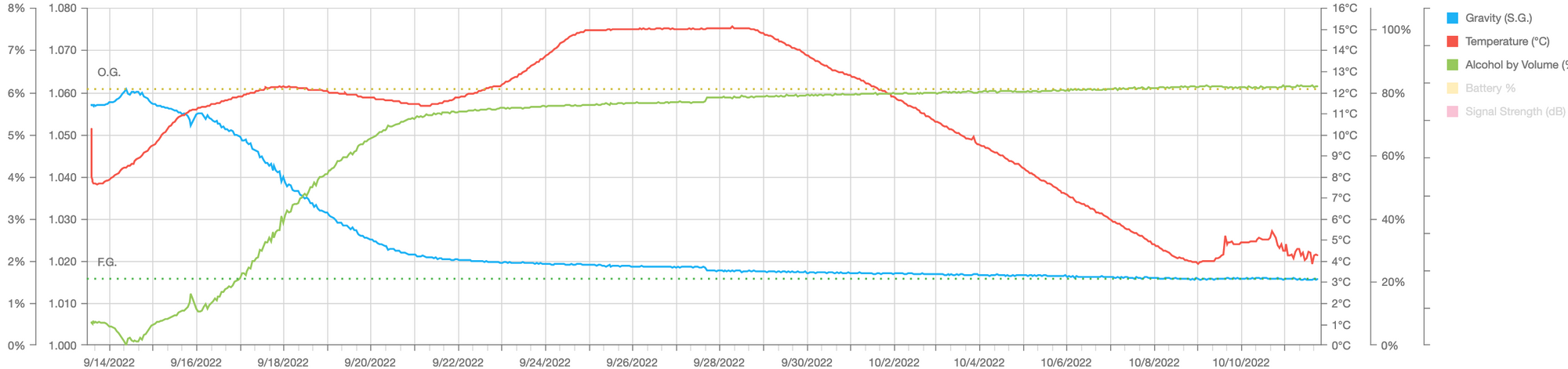

During the above, I added a RAPT Pill to the fermenter, so I have a much better visibility of temperature and fermentation/attenuation. I've added an image of the graph at the bottom of the screen, which I'll update regularly. Would be great if this could be embedded and updated in real time.

Not sure how the ABV has reduced, but I'm guessing it's just a function of the changing gravity...which is a function of the changing temp? Unclear.

What is interesting is that the gravity is reporting at 1.060 (at 8.7C). I did the standard calibration, but maybe that's not right? Main objective of using this, however, is to catch the end of the fermentation, when the SG starts to stabilise, so I can raise the temp for a diacetyl rest.

After ~5 days of fermentation, SG appeared to be stabilising (66% attenuation).

Started to raise the temp to 16C (+4C) for the same amount of time for a diacetyl rest (0.1 x 40 / 120hrs = ~1C per day).

After ~4 days at 15C (there appears to be a difference in temp between the temperature controller probe and the pill) I started reducing the temp again in 0.1C increments every 2 hours.

At this time the SG was 1.018, which was the initial target. I'm quite pleased by this given the Pill reported an OG of 1.060, which was higher than intended. This translates (according to the Pill) to a 71.3% attenuation and 5.92% ABV. Will be interesting to see what the refractometer says.

Despite the progress graph below, the fridge is set to 3.5C. The spike in temp at the end seemed to be caused when I removed the beer from the fridge to add the dip tube. Not sure why this should cause the temperature to jump so suddenly, but the fridge appears unable to reduce further since then. It's possible that the fridge's own thermometer is reading the temperature as low enough not to require further chilling.

I've dropped the temp on the freezer compartment to see if that has an effect. Normally this is as high as possible as it's just an energy drain that I don't use.

Fermentation Progress

The beer was transferred to a sanitised keg. As always, there was some left at the bottom of the FV for a little taste. The beer was very well attenuated - virtually no sweetness left in the beer, which might mean it's not a good example of a Pilsner, but certainly very drinkable, even at this early stage.

I also measure the final gravity with the refractometer but this reported 1.030, which I think can't possibly be correct.

What's left...

- Cold condition for 21 days at 3C before carbonating...then drink

Improvements for next time

- Recirculate the strike water before adding grains. Dead space under the grain basket might cause a bit of a temp difference - this just makes sure we're really at the correct temp.

- Check/reduce the pressure on the recirculation arm. It's possible that the water was hitting the sides of the grain basket instead of distributing over the surface of the grain.

- No mash out? I forgot this time, but when the mash time is up, raise temp to 76C to mash out before removing the grain basket for sparge.

- More sparge water. Pre-boil volume needs to be ~29L after the grain basket is removed to ensure 23L is left for fermentation. My final volume on this brew was a bit light at around 20L.

- Try and recalibrate the Pill to ensure it's measuring accurately.

- Try and recalibrate all measuring instruments to ensure they are at least consistent...otherwise, don't bother and just make good beer!

- Big kudos to the Bluestone liquid yeast I used for this beer. The flocullation was great and the yeast cake really solid which meant I was able to pull virtually all the beer off the top without sucking up lots of nasties.