Brew # 22 - Belgian Blonde Ale

Ingredients

- 4.5kg Continental Pilsener Malt (Weyermann Premium Pilsener)

- 560g raw cane sugar

- 200g Wheat Malt (Barrett Burston)

- 200g Aromatic Malt (Weyermann Caraaroma)

- 100g Rice Hulls

- 35g Hallertau Perle hops @ 6.7% AA (60 min)

- 2x White Labs WLP644 Saccharomyces "bruxellensis" Trois Yeast

Mashing

- Single mash of all grains for 60 mins @ 66°C in 20.5L water (approx. 3.6 litres per kg of grain)

- After ~30 mins start heating 15L of sparge water to 78°C

- Raise temp to 76°C for mash out

- Lift grain basket from wort

- Set temperature on Grainfather to 103°C

- Sparge (slowly) to 29L pre-boil (larger than normal due to boil time of 90 mins)

The extra sparge water meant I had ~2-3 litres of wort in addition to the 22 litres that made it into the fermenter. Probably don't need quite as large a pre-boil volume next time.

Boil

Boil time is 90 mins. Add hops with 60 mins remaining. Add raw sugar and 1/2 Whirlfloc tablet with 15 minutes remaining.

Cool

Chilled wort as quickly as possible to ~20°C.

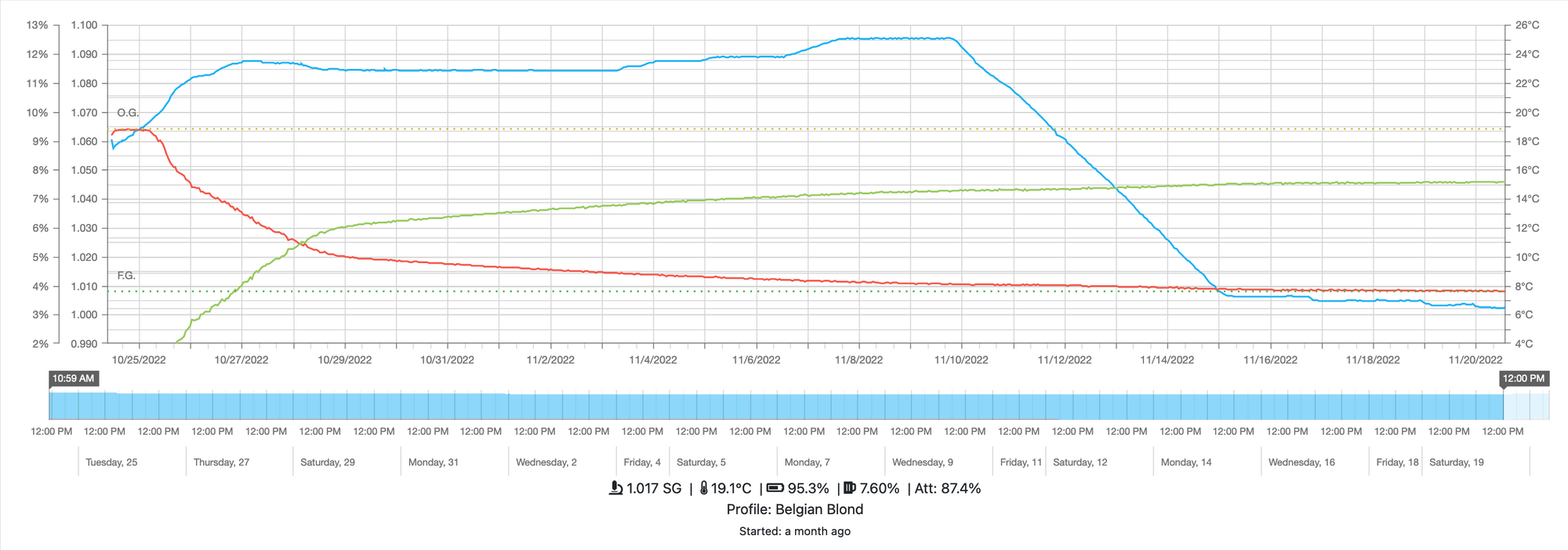

Target OG is 1.065 - the brew came in at 1.064 according to the refractometer. This was subsequently confirmed with the RAPT Pill.

Pitch

I bought 2x packs of liquid yeast so no starter is required this time around.

Aerated wort for 15 minutes after pitching with sanitised air pump and stone.

Added hydrometer/thermometer to monitor progress.

Fermentation

After pitching the yeast, slowly raise the temperature to ~23°C (this yeast has an optimum fermentation temperature between 21.1°C - 29.4°C).

I started this off at 0.3°C every 3 hours before realizing that would mean the alarm would start beeping at 5am in a couple of days. Changed to 0.2°C every 2 hours to give me a [more manageable] 24-hour cycle.

Fermentation started to slow after a week, but I hadn't yet hit my target of 1.012, so I started to increase the temp in 0.3°C bumps around day 9-10.

Achieved 1.012 after a couple of days, but it looked like the yeast hadn't completely finished, so I set the temp controller to continue to increase temp over 24 hours. This brought the final temp to ~25°C. Gravity dropped to 1.011 and appeared to hold signalling the end of fermentation.

Kegging

Once fermentation was complete, I reduced the temperature to 7°C to knock the yeast out of suspension and prepare for conditioning.

After ~1 week, I transferred into a sanitised, pre-chilled, pre-CO2'd keg for conditioning at 7°C for a further 2-3 weeks (as long as I can last).

Only thing remaining is to wait, carbonate, and drink.

Progress

Improvements for next time

- Reduce pre-boil volume.

- Fix the Grainfather so it doesn't leak from the recirculation arm.