Brew # 14 - Light American Lager

This is an all extract brew for a classic light (lite) American lager. Not technically challenging, I just fancied brewing something that was light and drinkable.

Start date: 07 Feb 2021

Equipment

- 19 litre stainless steel stockpot w/ lid

- Induction cooktop

- Fermentasaurus ("Fermus") w/ pressure kit

- Sanitiser in spray bottle

- Long handle spoon

- Funnel w/ strainer attached

- Digital thermometer

- Small grain sock

- 2 x 5kg Ice

Ingredients

- 1.9kg light dry malt extract

- 600g rice malt syrup

- 24g Hallertau Mittelfruh hop pellets (3% AA)

- 3 x White Labs WLP840 American Lager Yeast

Cleaning/Sanitising

Soak the Fermus in Sodium Percarbonate for a few hours (or days). Empty and rinse with cold tap water, and allow to drip dry before spraying with Iodophor (iodine) to sanitise. Rinse with cooled boiled water after min 5 mins.

Also sanitise an "old school" HDPE fermenting bin this time as we're going to need two fermenters, and the funnel and filter.

Brew Day

There are no grains to steep for this recipe, so it's a case of bringing the water required to boiling point as quickly as possible. This is a partial boil, so we need 11.5 litres in the stock pot to start with.

- Boiled kettle and added filtered water repeatedly until I had 11.5 litres of hot water in the brew pot

- Placed the stock pot on induction cooktop (set to 'Fry') and started to heat

- Added half (~1kg) light DME and half the rice syrup to the stock pot, stirring continuously

- Continued to heat the wort to boiling point (NO BOIL OVERS!)

- In the meantime, added ~11 litres of cold filtered water to fermenting bin and placed in freezer to chill

- Once the wort is boiling, intended to add the Hallertau hop pellets in the grain sock (I'm trying this for the first time to see if I can reduce the solids that end up in the fermenter)...but I totally forgot the grain sock and just added the hops straight to the boiling wort - bugger! (17:17)

- I tied a knot in one end of the grain bag and tried to place it in the stock pot like a hops fishing net. Not sure if this will be effective, but it might trap some.

- 10 minutes before end of the boil I added ~1tsp Irish moss - this is a light lager and I want it to be crystal clear

- After 60 minutes, turned cooktop off

- Added remaining (0.9kg) DME and 300ml rice syrup, stirring continuously

- I let stand long enough to pasteurise - in my case, that was 15 minutes whilst I dashed to the servo to get two bags of ice

- Emptied the bags of ice into a laundry sink (deep) and filled to half way with cold water

- The plug hadn't sealed fully so I could hear water running away. When I tried to reseat the plug it came out completely and the plug hole got filled with ice. A frantic few minutes ensued where I had to call for help to finally clear the plug hole and get the plug back in.

- One I'd got the plug back in, I placed the stock pot in the ice bath to cool

- I stirred the wort counter-clockwise to reduce the temp more quickly, taking care not to contaminate the wort with the ice water and to not splash the wort whilst hot

- At the same time, I swirled the ice water clockwise on the outside (as much possible before my hands froze each time)

- Once the wort got down to <40C (it felt like that, but I didn't want to put the thermometer in), I removed the fermenting bin with pre-chilled water and pout the wort in through the sanitised funnel and strainer

- The strainer (once again) proved difficult as the hops blocked the filter and prevented the wort from flowing into the fermenter - need to look for a less fine mesh

- Ended up just pouring the remaining wort directly into the fermenter without a strainer (which just makes it more like I'll have to rack across to a new fermenter in a couple of days)

- The total volume was bang-on 23 litres so I didn't need to add more water

- Placed the wort and yeast packs in the fridge set to 7C (because I forgot to take the OG)

- OG reading 1.042 (spot on!)

- Once the temp stabilised in the 7C range and the wort settled, there were a lot of solids in the wort (cold break and hop bits, which they are likely to be as this wasn't properly filtered) - this meant I need to rack to a second fermenter (Snubby Fermus)

- Before racking, I sanitised and rinsed the Snubby Fermus, drained, and the put it in the fridge for a couple of hours to bring the temp down closer to the 7C target

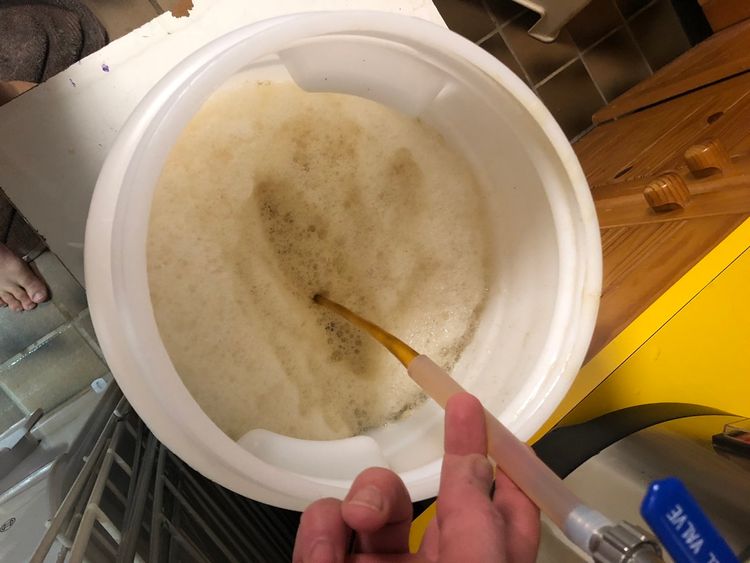

- I created a gravity transfer from the fermenting bin, making sure the wort splashed around to aerate during the transfer

- Once all the wort was transferred (except the trub at the bottom), I pitched the 3 packs of yeast (no prep or starter required for liquid yeast) and set the temp controller to raise the temp to 10C over the next 36 hours (~0.3C every 4 hours x 10 intervals)

Primary Fermentation

- I attached the PRV/spunding valve to ensure the Fermus doesn't explode

- I checked pressure regularly to make sure the PRV is set correctly (~10PSI)

- As this is a lager, fermentation was expected to take longer than normal, and after a couple of days I could see a very white krausen forming on the top of the beer

- ...but no gas

- The PRV was not registering any pressure increase in the Fermus, and that's the way it stayed for nearly two weeks

On Feb 19th (12 days after starting) I started to raise the temp in 0.3C increments every ~2 hours. This was mostly because I've heard this yeast can benefit from a diacetyl rest, but also to see if I could generate any more yeast activity.

I've heard that this yeast (White Labs WLP840 American Lager) can work very quickly, but I really wasn't expecting things to happen in 3 days, and at 10C. The beer is still quite cloudy, too, which I wasn't expecting. Maybe the lagering will clear that up?

Anyway, I continued to raise temp to ~15C. After a week at this temp, I crashed again to 3C.

Kegging

I think I did this around ~7th March. House renos mean I've not been paying as much attention as I should have been!

- Chilled a sanitised keg to 3C

- Pressurised to ~8PSI

- Performed closed transfer of beer from Fermus to keg

- Lagered in the Keezer for 2 weeks at ~4C

Coming next...

- Attach CO2 to keg at 49PSI for 36 hours to carbonate

- Drink

Improvements for next time

- Check for CO2 leaks - when I performed the transfer I think I discovered this was from the spunding valve. Make sure it's tightly sealed next time.